Metal LED Cartesian Lattice

Introduction to Sense Cube, printable lens supporting Truss Cube

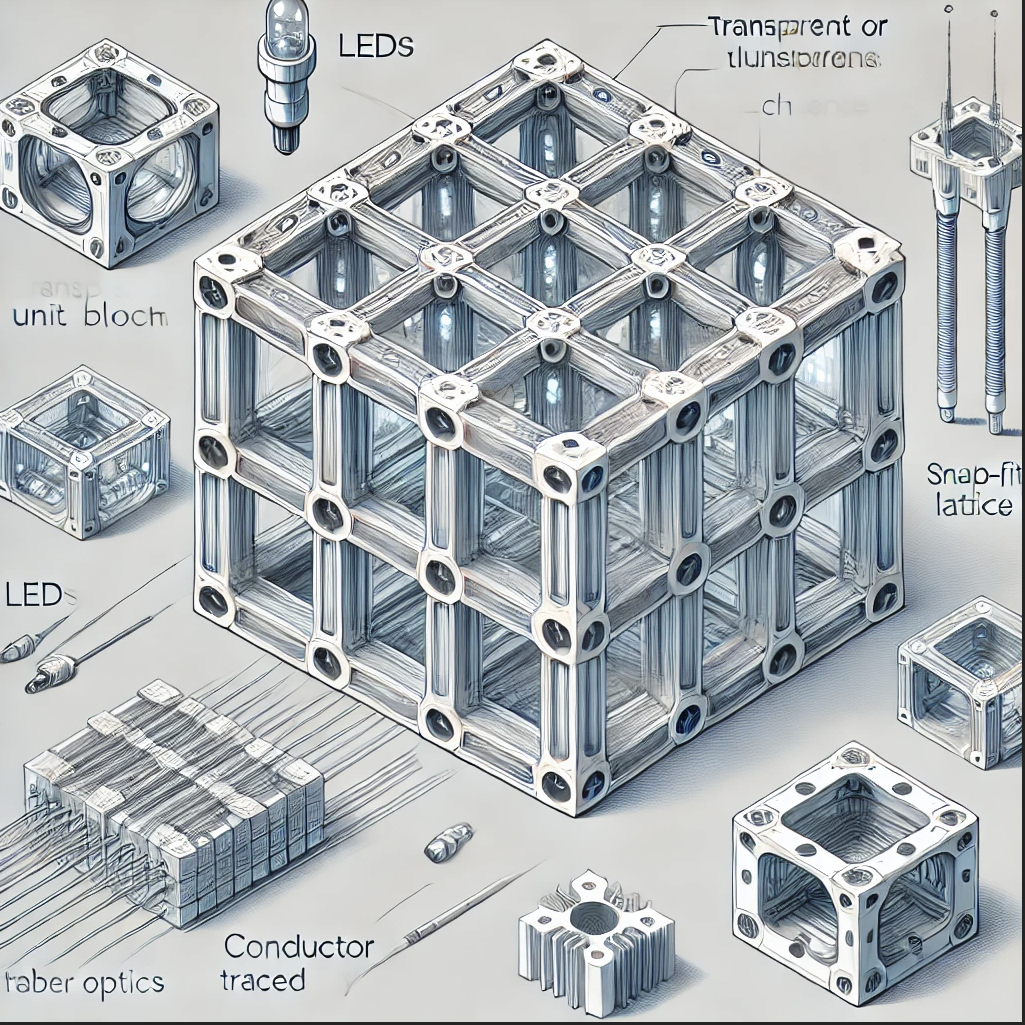

Metallic SLED 3D Printable Lens Truss Matrix

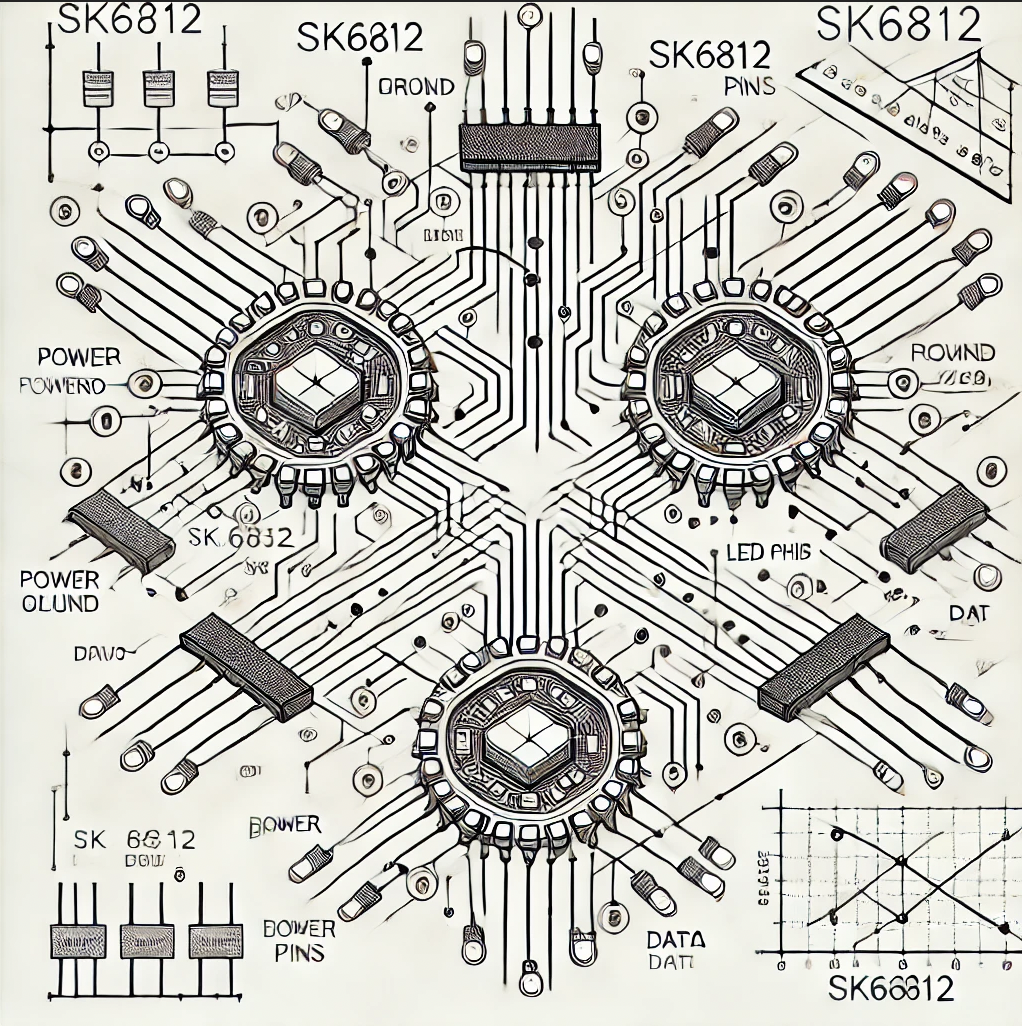

Surface mount LEDs in a corner array of orthogonal orientation to scan space out each covering 180 degrees of standard cartesian with a 90 degree offset. A very simple engineering drawing that describes one unit block sweeping out. Perhaps something a CAD system could interpret for a 3D printer, let's consider light options. An SLED offers well designed balancing channels, although LEDs and design work towards the same goal.

SLED would offer point of reference channels, an easier starting point to test engineering designs from hardware to lightware of anticipated to resulting measure, understanding.

LED Slices and Polarized Heals – Enhancing Precision in Light Management

Introduction to SLED Slices

The Superluminescent Diode (SLED) slices form the next critical layer in the spherical matrix system. These slices operate in a similar manner to a finely sharpened blade, cutting through the incoming light and dividing it into manageable segments, or “slices.” This process is critical for separating different portions of the optical data stream, allowing the system to analyze each slice with precision.

Each SLED slice operates on specific wavelengths of light, which are divided according to their frequency and intensity . This segmentation allows the system to handle light in smaller, more controlled units, ensuring that each portion of the light is analyzed in detail before being recombined into a complete image or dataset. The SLED slices are highly tuned to the specific needs of the matrix, ensuring that the optical data is divided in a way that maximizes accuracy and minimizes noise.

Polarized Heals: Correcting, Smoothing, and Redistributing Energy

Once the light has been segmented into slices by the SLED system, the spherical matrix turns to polarized heals for further refinement and correction of the optical data. The role of these polarized heals is not merely to align light waves but to redistribute energy and smooth out irregularities, ensuring that the system can process the data with maximum clarity and precision.

Polarization plays a vital role in this process. Light waves naturally align themselves in certain directions as they pass through different mediums, but polarization mismatches—caused by misaligned wave orientations—can introduce distortions and reduce the integrity of the optical data. The polarized heals step in to identify and correct these mismatches, aligning the light waves so that they travel through the system smoothly and without introducing noise or errors.

Smoothing the Magnitude through Comparison

The polarized heals go beyond basic alignment. By applying a comparison process , they work to smooth out the magnitude of the light waves passing through the system. This is done by evaluating the overall intensity and orientation of the incoming waves and then making real-time adjustments based on the mean value of the data.

If a certain portion of the light exhibits excess energy or deviation from the optimal orientation, the polarized heals apply an extra impulse back into the data stream. This redistribution of energy effectively smooths out any spikes or irregularities, similar to how a dampened string on an instrument gradually returns to a state of harmonic balance after being plucked. This comparison process ensures that the system maintains an even, balanced flow of light, avoiding disruptions that could interfere with the precision of the final data output.

Lattice Flex for Health: The Key to Adaptation

A unique characteristic of the Metal LED Cartesian Lattice is its ability to "flex for health," much like the exercise of living organisms. This process involves subtle adjustments within the lattice that balance material density and distribute lightware energy input efficiently. As the structure stretches and contracts, it redistributes stress and heals itself, ensuring that local energy requirements are met without compromising structural integrity.

Similar to how muscles grow stronger and more resilient through exercise, the lattice adapts to its energy environment through motion, optimizing its performance in real-time. This flexibility allows the system to manage various energy transactions while promoting long-term durability. When the right conditions are met, this lattice flex acts as a gentle reminder that movement—whether in physical structures or biological systems—is essential for sustained health and performance.

The polarized heals act as vibrational redistributors, constantly monitoring the flow of light and adjusting the energy distribution as needed. At specific moments of high interaction, the system uses the excess energy generated by polarization mismatches to redistribute energy across the wavefront , ensuring that the light remains coherent and smooth as it moves through the matrix.

Matching Digital Photocells with Optical Clarity

This energy redistribution is closely linked to the interaction between the polarized heals and the digital photocells embedded within the matrix. The polarized heals ensure that the optical clarity of the system is always in sync with the digital components. As light is processed and adjusted, the digital photocells receive the data and translate it into a form that can be analyzed or further processed.

By smoothing out the light and redistributing energy at key moments, the polarized heals ensure that the data reaching the photocells is clean and precise. This process is akin to fine-tuning an image, ensuring that every pixel—or in this case, every photon—is exactly where it needs to be for optimal clarity. The interaction between the optical system and the digital photocells creates a feedback loop, where the clarity of the optical data informs the digital processing, and vice versa.

Combining SLED Slices and Polarized Heals

The combination of SLED slices and lattice flex healing or balancing allows the spherical matrix to achieve a level of precision that is difficult to match with traditional optical systems. By slicing the light into smaller, more manageable portions and then correcting any polarization mismatches, the system is able to optically process data with a high degree of accuracy.

This process ensures that each slice of light is handled in isolation, allowing for more granular control over the data. Once the slices have been fully processed and corrected, they are recombined into a coherent optical stream, which can then be analyzed as a complete dataset.

The beauty of this system lies in its ability to dynamically adjust the slicing and polarization processes in real-time. As the light changes or as new data enters the system, the SLED slices and polarized heals can adjust their settings to ensure that the data is always being handled with the highest level of precision.

Science Tool

An interactive design would be a trussed lattice with individual unit cubes all 90 degree cut so that there could be flat traces for ribbon cable, configurable channels between the nodes. The type of flat wire ribbon that's well proportioned to the current balance of the design. This could also be entire arrays of LED or actual high density camera sensor arrays set properly across an optically transparent as possible lattice even if it's in a fluid that maintains an optical buffer.

<= Back

<= Home (Splash)